Revolutionizing Materials Science: Exploring Combinatorial Deposition and Sybilla Equipment

posted Nov 15 2023

Revolutionizing Materials Science: Exploring Combinatorial Deposition and Sybilla Equipment

What Is Combinatorial Deposition All About?

Combinatorial deposition is a versatile process that allows for the efficient preparation and measurement of a vast number of compounds in a single operation. In the field of biology, this methodology proves especially potent for creating libraries of diverse pharmaceutical combinations, each with unique curative effects.

Combinatorial Deposition for Thin Films: State of the Art

In the realm of thin films, the combinatorial approach empowers researchers to generate extensive libraries of material properties, including phase diagrams. This is achieved by varying parameters such as elemental composition, structural patterns (such as thin film thickness, nanoparticle sizes, or aggregate dimensions), and combinations of different materials in proximity, as seen in PN junctions. The high throughput of this methodology enables systematic investigations of trends in complex, multi-dimensional systems like multi-element thin films, all aimed at optimizing their structural and functional properties.

While combinatorial deposition historically found limited application in the semiconductor industry due to the restricted set of elements, its potential in exploring oxide thin films is nothing short of astounding. With over 40 different elements that can be combined in binary, ternary, quaternary, or more complex materials, the possibilities are virtually limitless. Moreover, in oxide thin films, structural properties greatly influence functional properties, leading to exponential combinations. These thin films often exhibit multi-functional properties with intricate figures of merit, making optimization challenging, as improvements in one property can decrease the performance of others. Adding patterning effects in 2D or 3D, along with various substrate influences like epitaxy, makes traditional investigation methods inadequate.

Combinatorial Deposition for Oxide Thin Films and Sybilla Equipment Disruption

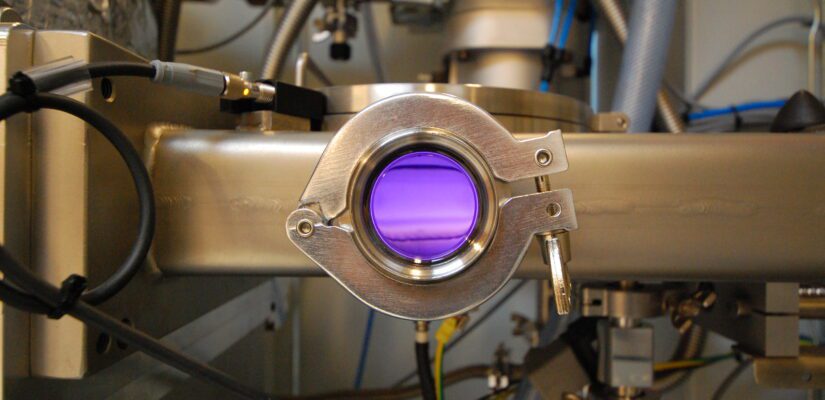

Sybilla equipment offers a unique approach to combinatorial deposition. It goes beyond traditional phase diagrams based on elemental stoichiometry and supports micro-combinatorial gradients at scales below 1 micron and architecture-combinatorial processes with additive growth. This innovative approach can yield the equivalent of thousands to millions of different materials in a single thin film growth experiment, providing significant cost and time savings.

Moreover, Sybilla equipment allows for in-depth investigations into process optimization. Precursor flows, including impinging rates, can be precisely modeled and quantitatively calculated, enabling researchers to explore the influence of precursor chemistry (ligands) on the structural and functional properties of materials, even when their chemical compositions are identical.

As an additional advantage, the Sybilla Equipment combinatorial facility enables the rapid reproduction of conditions identified at a specific position across a full wafer due to highly controlled and reproducible flows.

Why Choose Sybilla Equipment for Combinatorial Deposition?

- Accelerate your research with the equivalent of over 10 thin film growth reactors in a single tool.

- Enhance research accuracy with the ability to investigate trends through continuous variation of material properties.

- Easily transition your combinatorial recipes to production and large wafer scales.

- Gain deeper insights into your processes and chemistry.