ABOUT - ABCD-technology

Founded in 2006, ABCD Technology Sarl is a Swiss spin-off from EPFL (Swiss federal Institute of Technology, Lausanne).

It provides to its customers unique equipment to deposit top quality and disruptive oxide thin film.

Highly agile and powerful, “Sybilla” equipment combines the possibility to deposit multi-element and multi-functional thin film with either unprecedent homogeneity on large substrates or disruptive 3D-architectures by combining the use of combinatorial and 3D-printing additive facilities, enabling improved performances or totally new thin film materials and devices.

We foster your future devices with unmatched material properties towards new functionalities, miniaturization and integration capacities in the “More than Moore” vision.

Who We Are

ABCD Technology is part of a network of sister companies with complementary skills to provide a complete and optimized solution to the highly challenging thin film deposition field.

Our staff owns, among others, state of the art know-how and skills in vacuum, thin film growth, organometallic chemistry, optics, laser and particle beams, materials science and nanotechnologies, in addition to the top skills in mechanical engineering required to build such equipment.

To correctly address this complexity, the strategy has been to grow a strong network of partners to pursue parallel development of complementary specific expertise and know-how.

These competencies and expertise are distributed in several inter-connected, but independent companies, each one strongly focused on its core-competences and core-business.

This strong network of highly specialized interacting skills and competencies make of ABCD Technology’s disruptive Sybilla equipment a tremendous opportunity and an unmatched solution for the most demanding thin film developers adopting it.

What We Do

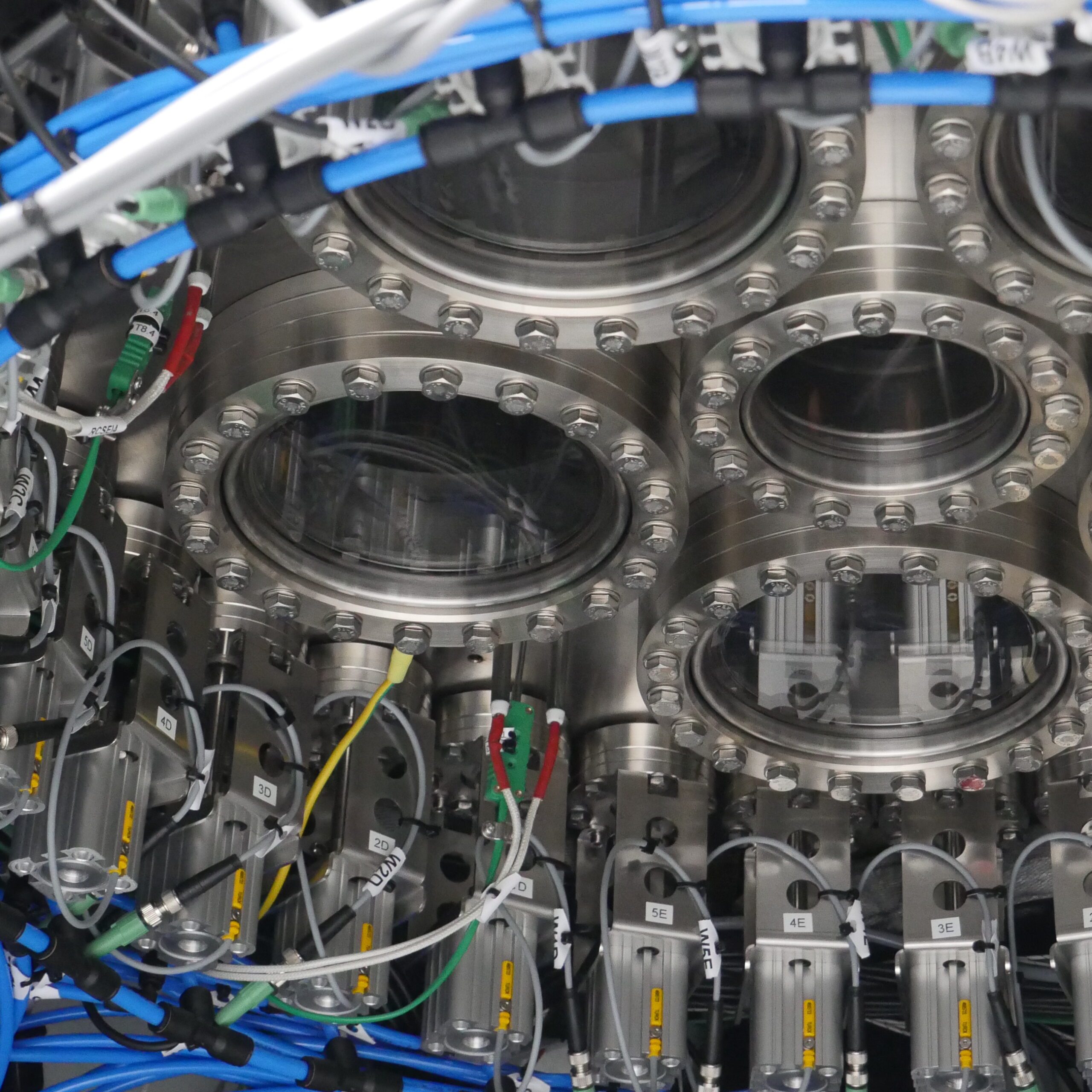

ABCD Technology SYBILLA series thin film deposition equipment are based on Chemical Beam Epitaxy (CBE) technique, merging high agility, flexibility and speed for R&D purposes with a robust methodology for production.

Our equipment allows to produce high quality complex thin film for mature and emerging markets such as (but not limited to) microelectronics, photonics, optronics, renewable energies, catalysis, bio-compatible coatings, or decorative coatings.

Our equipment is particularly well-optimized to address multi-element oxide thin film, offering highly eco-sustainable materials, that display a plethora of different functional properties, but III-V or II-VI semiconductors can also be grown.

Chemical Beam Epitaxy (CBE) is a line-of-sight deposition technique to grow thin film using chemical precursors in high vacuum (below 10-5 mbar).

It was developed in the 1980’s from the merging of MBE (Molecular Beam Epitaxy) and CVD (Chemical Vapor Deposition) to deposit III-V semiconductor thin film.

Several names have been attributed to slightly different versions of the technique such as Gas Sources MBE (GSMBE), Metal-organic MBE (MOMBE), High-vacuum CVD (HV-CVD) or Chemical Beam Vapour Deposition (CBVD).

CBE (and its variant techniques) have demonstrated excellent results over the years as reported in the literature, proving experimentally their advantages over competitor techniques for:

- Controlled deposition and doping of multi-element materials

- High composition and thickness uniformity

- Upscaling to large substrates

- Wide range growth rate tunability

- High reproducibility from batch to batch